Sustainability

Terminal B to C Connector at Boston Logan International Airport

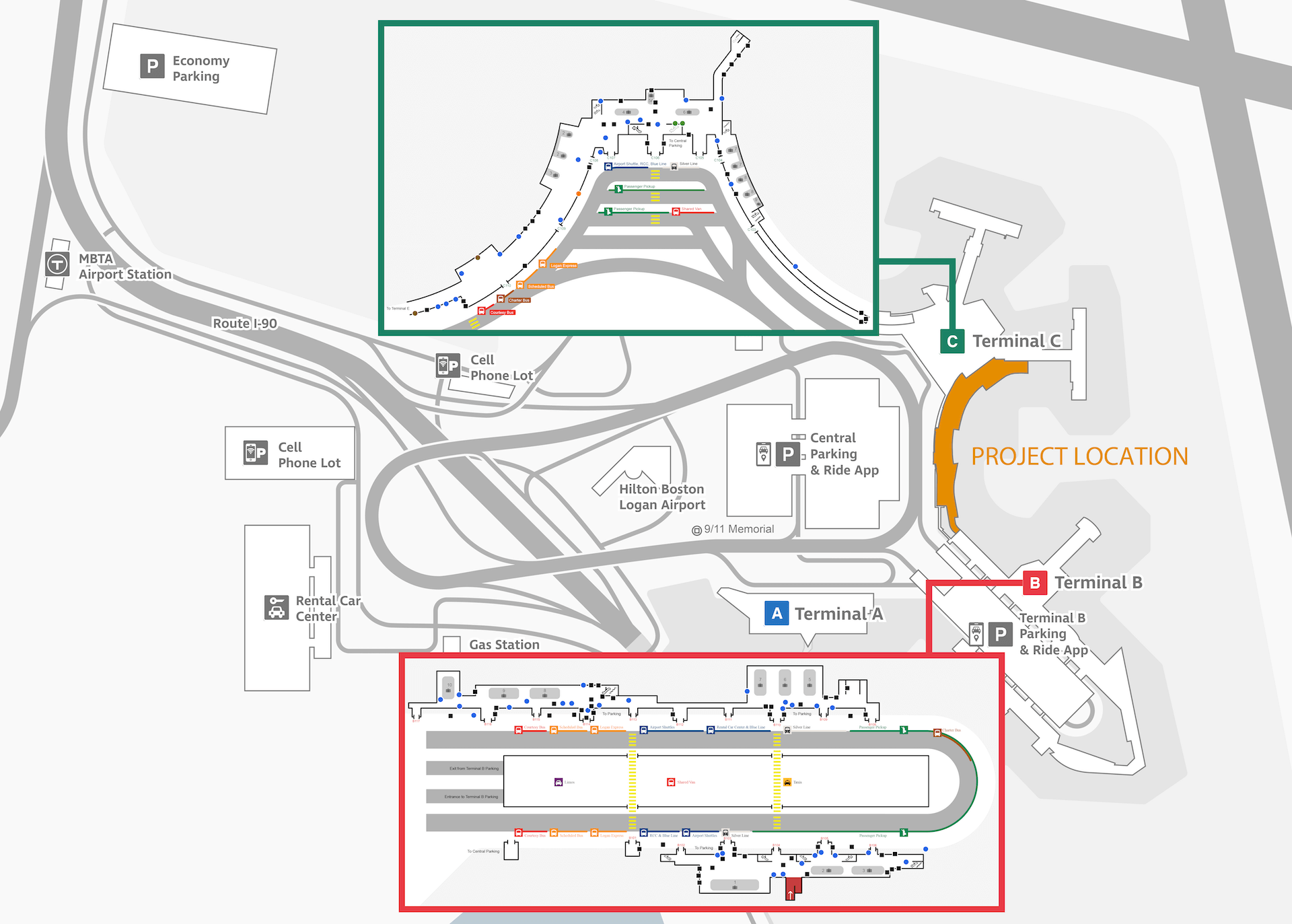

Project Overview

The Terminal B to C Connector established a post-security connection between the terminals at Boston Logan. Along with the associated Terminal C Optimization project, it offered improved efficiency, functionality, and connectivity for passengers, tenants, and airport operators alike. The project added additional operational and administrative spaces and travelers now enjoy enriched lounge amenities, technologies and convenient concessions.

Other terminal improvements include welcoming rest areas, accessible changing areas for parents, a variety of local products provided throughout terminal concessions, and accommodation of pet needs through service animal relief areas. Backbone building systems infrastructure was all raised above a new design flood elevation in alignment with Massport’s resiliency objectives.

The project opened in 2022 and received the LEED Gold designation in 2023 with 60 points achieved.

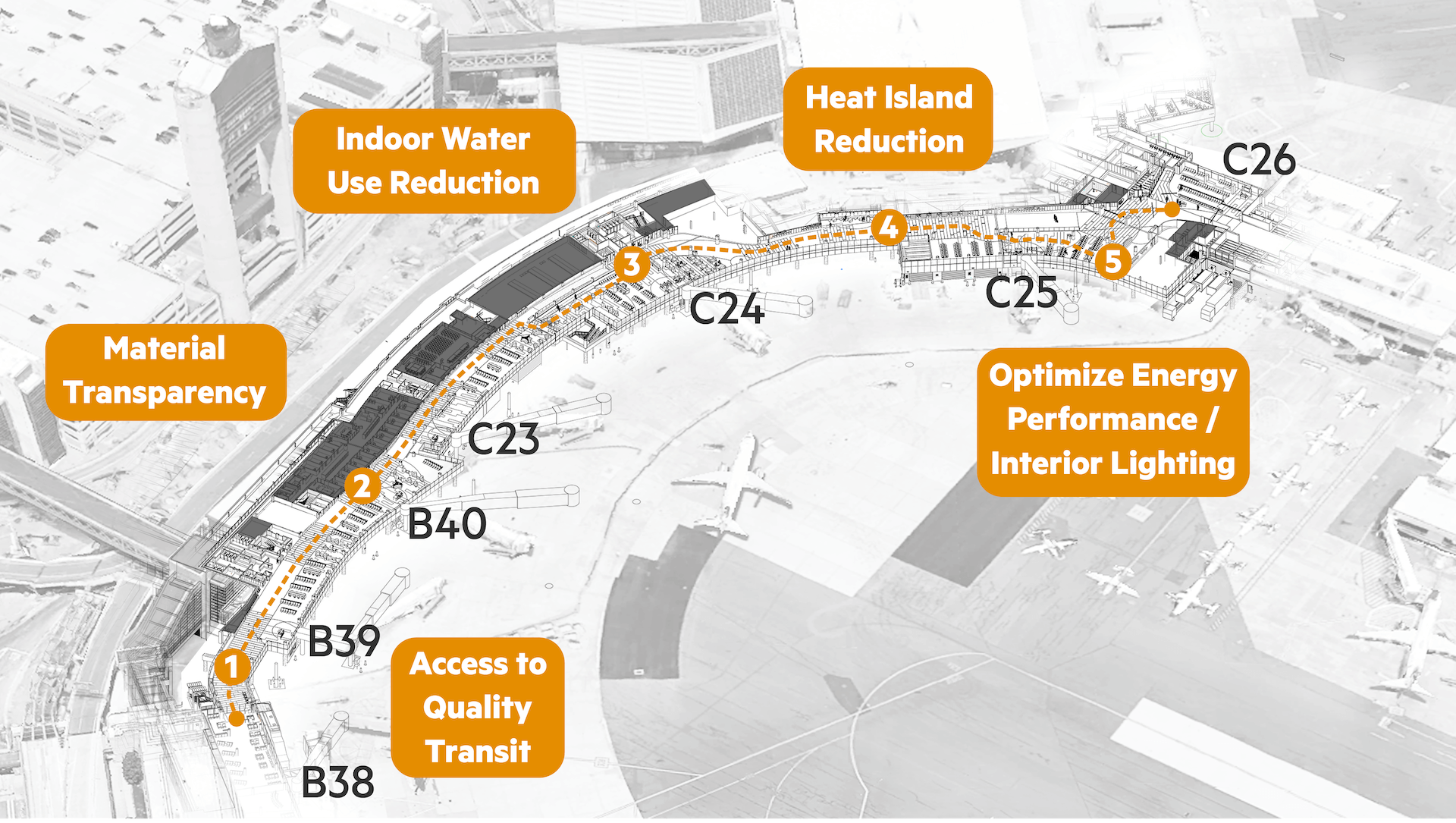

The self‐guided tour consists of a series of stops that highlights the sustainable aspects of the

space. It is encouraged that guests stop at each of the following stops on the figures as they

walk through the Connector to learn more about:

- Access to Quality Transit

- Material Transparency

- Indoor Water Reduction

- Heat Island Reduction

- Energy Optimization

All strategies earned the project one or more points through the LEED certification process.

LEED Overview

LEED-certified buildings save money, improve efficiency, lower carbon emissions, and create healthier places for people. They are critical to addressing climate change and meeting ESG goals, enhancing resilience, and supporting more equitable communities. To achieve LEED certification, a project earns points by adhering to prerequisites and credits that address carbon, energy, water, waste, transportation, materials, health and indoor environmental quality.

Self-Guided Tour Overview

The self-guided tour consists of a series of stops that highlights the sustainable aspects of the space. It is encouraged that guests stop at each of the following stops on the figures as they walk through the Connector to learn more about Access to Quality Transit, Material Transparency, Indoor Water Reduction, Energy Optimization, and Heat Island Reduction. All strategies earned the project one or more points through the LEED certification process.

Self-Guided Tour

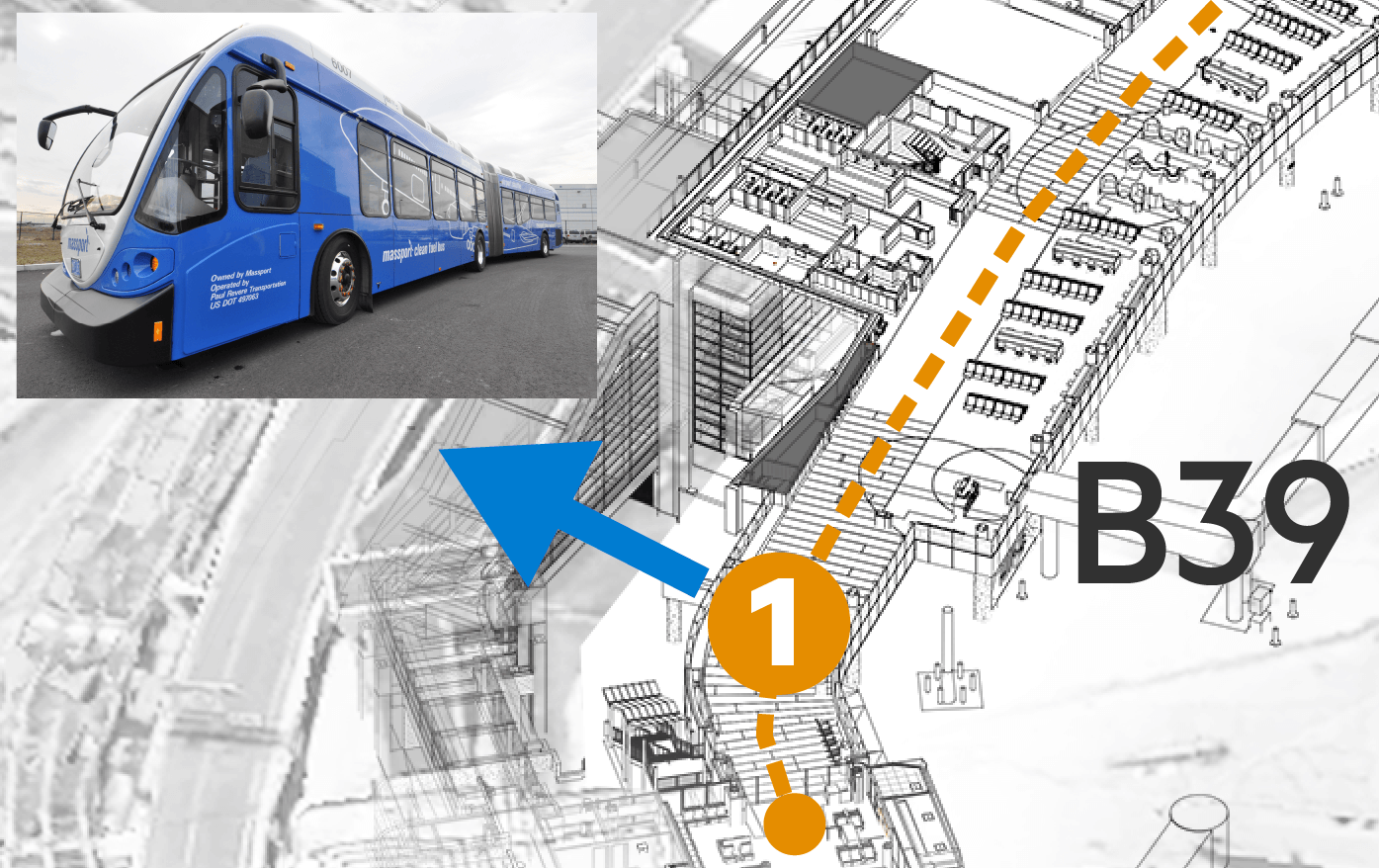

Access to Quality Transit

Boston Logan is accessible from a robust network of transit options. Access to transit is particularly beneficial for young people, the elderly, and people who cannot afford to own cars. Nearly all forms of public transit create fewer greenhouse gas emissions per passenger than single-occupancy vehicles. The surrounding transit options are also less expensive than car travel and parking - The Silver Line Rapid Transit Bus, for example, is free from South Station and the Blue Line Subway and Ferries are low-cost and service the area often.

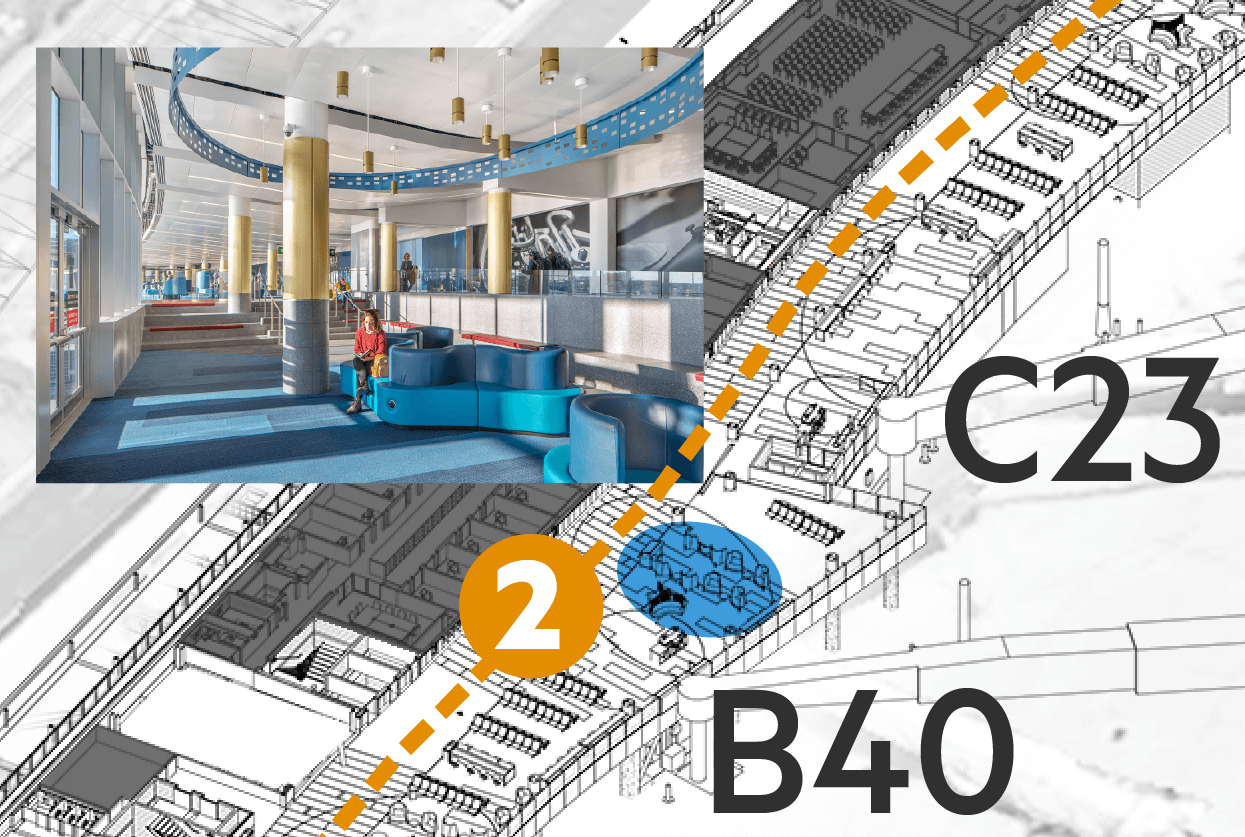

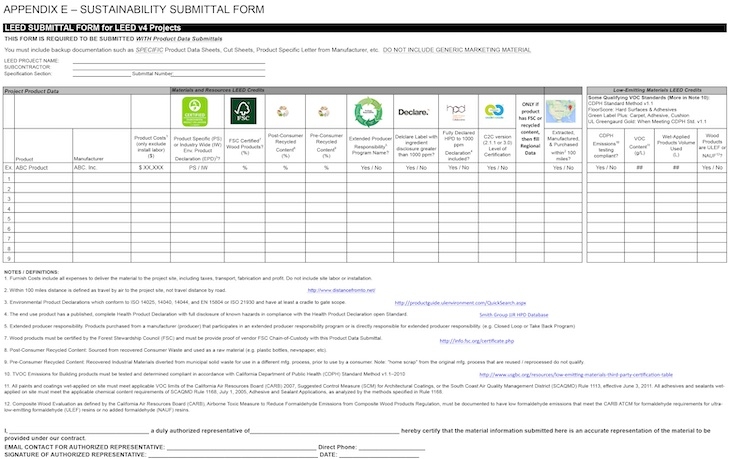

Material Transparency

Material transparency encourages the use of products and materials for which life-cycle information is available and that have environmentally, economically, and socially preferable life-cycle impacts. Environmental Product Declarations (EPDs) are a standardized way of communicating the environmental effects associated with a product or system's raw material extraction, energy use, chemical makeup, waste generation, and emissions to air, soil, and water. The construction team collected over 20 different permanently installed products sourced from at least five different manufacturers with EPDs.

The identified seating area outside gate B40 features products and materials with available third-party verified EPDs that informed the finish selection process.

Indoor Water Reduction

Potable water usage in buildings constitutes a large portion of freshwater consumptions. Strategies to reduce potable water use in buildings entail the selection of efficient plumbing fittings, fixtures, and equipment. The WaterSense label was developed by the U.S. Environmental Protection Agency to identify these efficient fixtures and ensure that higher efficiency does not come at the cost of performance.

This project reduced indoor water use by 33% and utilized WaterSense labeled fixtures. The Eco-Power High-Efficiency Toilet Flush Valve only utilizes 1.28 gpf (gallons per flush) which is below the 1.6 gpf baseline.

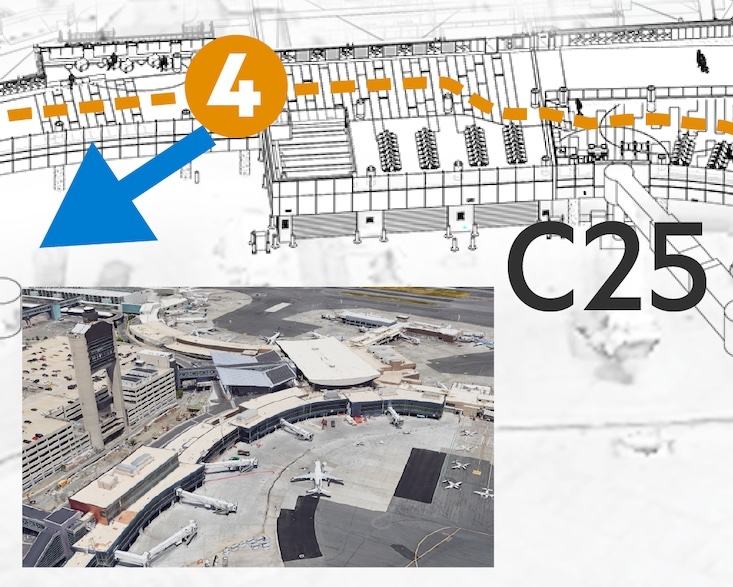

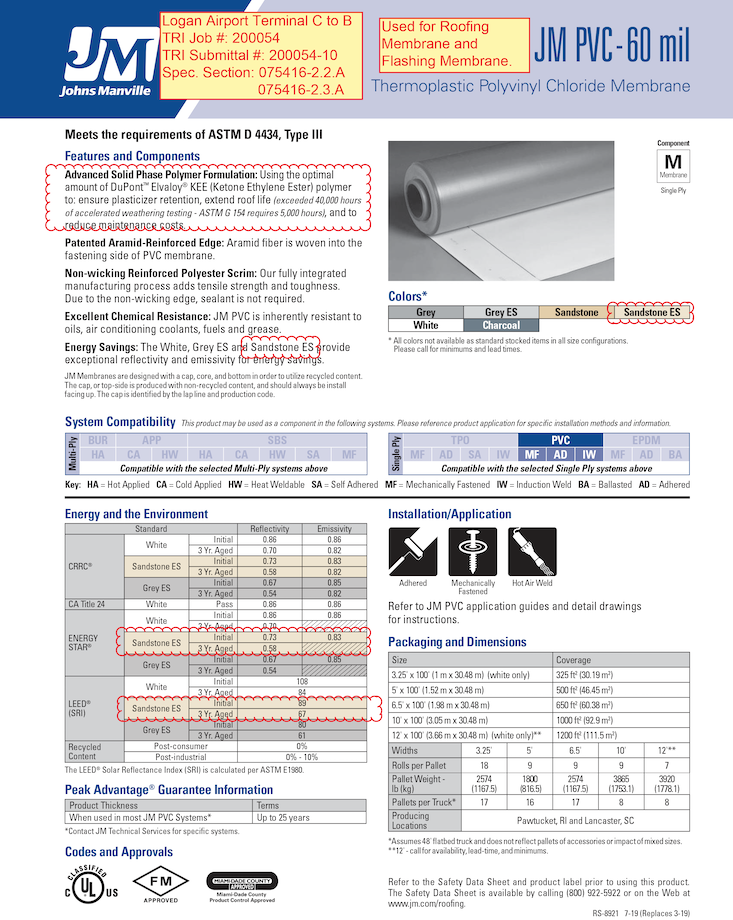

Heat Island Reduction

Dark, nonreflective surfaces used for parking, roads, roofs, walkways and other hardscapes absorb the sun's warmth and radiate heat, creating heat islands. Temperatures in urban areas can be warmer than surrounding suburban and undeveloped areas by 1 ‐ 3 °C (1.8 ‐ 5.4 °F) and as much as 12 °C (22 °F) warmer in the evenings.

A roof's Solar Reflectance Index (SRI) measures the material's ability to reject solar heat which helps reduce heat islands that can have numerous negative consequences to plants, animals, and human health because of exposure to increased ground-level pollution.

The roofing material used on this project is from Johns Manville. The sandstone color provides the material with an SRI value of 89 (out of 100), which is highly effective in reducing heat islands.

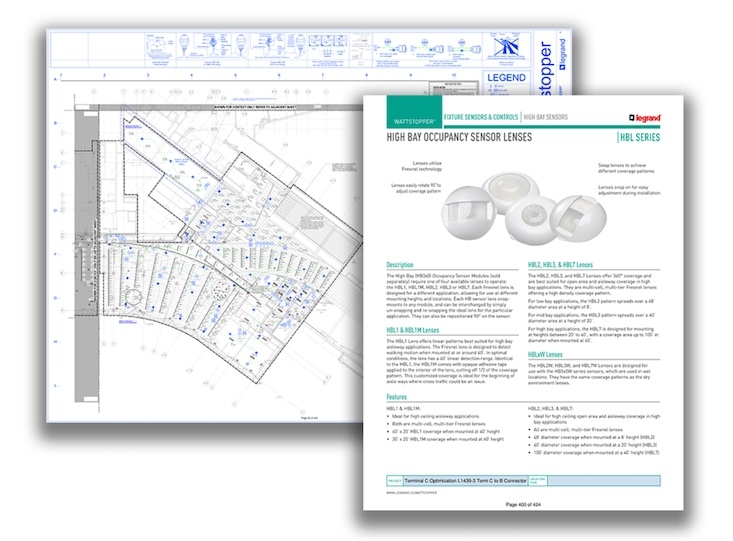

Optimize Energy Performance

An optimized building design can substantially reduce energy use - often for a modest initial cost with a short payback period - when it includes load reduction, improved mechanical system efficiency, and smart operation strategies. The design team included an Energy Simulation which allowed the team to adapt the design throughout the phases to optimize energy performance with a 21% total energy cost savings.

Some ways energy use was reduced was through the use of LED lighting with programmed zones that dim to 10% when unoccupied at night, with a maximum of 80% during daytime when occupied to conserve electricity.

The curtain wall all along the concourse features View Glass, electrochromic dynamic glazing, which intelligently responds to the sun levels and adjusts to maximize daylight and views while minimizing heat and glare.

Additional Project Information

- Architect: Fennick McCredie Architecture

- Contractor: Suffolk Construction

- LEED BD+C v4: Certified September 18, 2023

- US Green Building Council LEED Project Page

- Green Building Information Gateway Project Page